quv test for paint|How many hours in a Q : agency Sunlight, heat, and moisture cause millions of dollars of material damage every year. The QUV accelerated weathering tester reproduces the damage caused by sunlight, rain and dew. In a few days or weeks, the QUV can generate the same degradation tht occurs over months or years outdoors. The QUV tests materials by exposing them to alternating cycles of ultraviolet (UV) . Resultado da 2 dias atrás · Bosch brings together comprehensive expertise in vehicle technology with hardware, software, and services to offer complete mobility solutions. Discover the entire portfolio Industry and trades

{plog:ftitle_list}

WEBOs códigos promocionais oferecem aos usuários bônus especiais ao utilizarem os serviços oferecidos pelo Rivalo. A plataforma dá prêmios mensais ou aumento .

Q-Lab Corporation is a global provider of material durability testing products. We design and manufacture Q-PANEL standard test substrates as well as weathering, light stability, and corrosion testers. Q-Lab also offers A2LA .

Accelerated Gloss Retention Testing: QUV-A. Accelerated gloss retention testing was performed by drawing down paints with a 3 mil bird bar on aluminum panels and allowing them to dry overnight. The panels were placed in a QUV .

What is ASTM D4547 (QUV Exposure) Testing and Why is it Impo

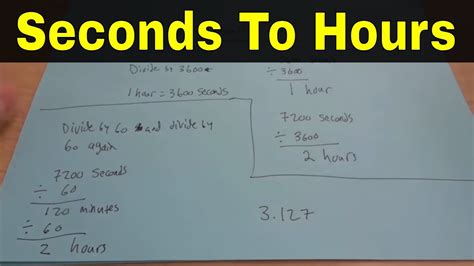

How many hours in a Q

Sunlight, heat, and moisture cause millions of dollars of material damage every year. The QUV accelerated weathering tester reproduces the damage caused by sunlight, rain and dew. In a few days or weeks, the QUV can generate the same degradation tht occurs over months or years outdoors. The QUV tests materials by exposing them to alternating cycles of ultraviolet (UV) . Michel Comtois is an accomplished founder and CEO of Micom Laboratories Inc., an ISO/IEC 17025 (2017) A2LA-accredited independent laboratory specializing in product and material testing services.Before .The QUV test uses only light from the UV spectrum (340 nm). By default, this is UVA light, but it is also possible to test with UVB light (313 nm). In most cases, testing is done with a combination of light and water vapor. This simulates what happens in practice during the day and night (sunlight and dew) Often this is 4 hours of light and 4 . In QUV and xenon testing, the Ultramarines all faded about as badly as fluorescent pigments in acrylic paint, finishing to a cool, chalky gray. Because of these problems, it may be necessary to test samples with high proportions of a cobalt or ultramarine pigment only in Arizona; or at least to pair artificial light exposure testing with .

Loss of paint color is caused by ultraviolet (UV) degradation of the pigment and resin system. Color is calculated in Hunter units, according to ASTM D2244, and . • A ccelerated Indoor Weather Testing (QUV): Sherwin-Williams uses QUV Testing in its global Applied Science and Technology labs. Coated panels are placed inside a QUV Testing .The QUV simulates this using a unique condensation mechanism. During the condensation cycle, a water reservoir in the bottom of the test chamber is heated to produce vapor. The hot vapor maintains the chamber at 100% relative humidity, at an elevated temperature. The QUV is designed so that test specimens form the50 years of making testing simple. In 2020, the QUV tester is celebrating 50 years as the world's most widely used weathering tester. QUV users can now enjoy many of the same upgrades found on new Q-SUN "E" Model testers, including:QUV - The World's Most Widely Used Weathering Tester . and reproducibility of your test program. Visit our standards page for more information. Easy to Operate The QUV tester’s simple, proven design makes it easy to install, easy to use, and almost maintenance-free. It operates completely automatically, 24 hours a day, 7 days a week.

Israeli Standard No. 935, Road Marking Paint Israeli Standard No. 1086, Aluminum Windows NISSAN M0007, Fluorescent UV/Condensation Test JIS K 5600-7-8, Testing Methods for Paints . Microsoft Word - QUV-Test Methods-Standards-LU-8012(08-07).doc Author: Danica ZeiseInitial QUV tests caused severe cracking in 200 to 400 hours. This is much sooner than conventional coatings used for the same purpose. However, after 3 years of continual reformulation and retesting in the QUV tester, the coating was improved so that various formulations could withstand 2,000 to 4,000 hours in the QUV tester - much better than .The QUV UV test chamber's condensation system realistically simulates dew and accelerates its effect using elevated temperature. The condensation process automatically purifies the ordinary tap water used in the system. . Standard Practice for Fluorescent UV-Condensation Exposures of Paint and Related Coatings.

QUV/uvc Accelerated Weathering Tester QUV is the the world's most widely used weathering tester. The NEW QUV/uvc tester features: The new Gen 4 Controller with dual touch-screen displays and 8 languages; UVC lamps to deliver light at 254 nm and the SOLAR EYE system to precisely monitor and control UVC dosageAccelerated Testing: The QUV tester quickly simulates long-term outdoor conditions in a matter of days or weeks, providing rapid feedback on material durability. . trim, and paint. Interior Materials: Evaluating the durability of interior materials like dashboards and upholstery when exposed to UV light. Performance Verification: .The Atlas UV Test is an economical instrument for fluorescent UV and condensation weathering test methods which uses UVA 340, UVB 313, or UVA 351 fluorescent bulbs for a variety of applications. English. This site in other languages: . Standard Practice for Fluorescent UV-Condensation Exposures of Paint and Related Coatings; ASTM D4799

The QUV accelerated weathering test simulates and reproduces the damage caused by sunlight, rain, and dew. While damage done through exposure to the elements typically takes a few months to even years, we're able to simulate the same degradation process . However, testing this in an accelerated way with artificial light is difficult and can be inaccurate, especially for long-lasting systems. Super durable TiO2 grades are designed to give optimal protection against UV light. This is . In paint systems dependent on protection provided by pigment for light stability, durability is more dependent on relatively small variations in PVC. . For example ASTM D4587 Fluorescent UV-Condensation Test (AKA QUV) has 4 different cycles that provide somewhat different results depending on the cycle selected. Lastly, I would not recommend . During the QUV condensation cycle, a water reservoir in the bottom of the test chamber is heated to produce vapor. The hot vapor maintains the chamber environment at 100% relative humidity, at an elevated temperature. The QUV is designed so that the test specimens actually form the side wall of the chamber.

Scope of applicationDyestuff, Footwear,Paint Coating, Packaging, Outdoor, Building Home, Car, Plastic Rubber, Testing and so on The QUV accelerated weathering tester reproduces the damage caused by sunlight, rain and dew. In a few days or weeks, the QUV can generate the same degradation that occurs over months or years outdoors.ASTM G154 is integral to various ASTM test methods, including ASTM D1248, ASTM D5208, and ASTM D5894, which incorporate QUV exposure along with ASTM G85 for cyclic corrosion testing. After materials undergo exposure to ASTM G154, a range of measures can be employed to assess the aging impact; consult ASTM testing and Coating Testing for more .The QUV test chamber, on the other hand, does not attempt to reproduce sunlight, just the damaging effects of sunlight that occur from wavelengths between 295 nm and 400 nm. It is based on the concept that, for durable materials exposed outdoors, short-wave UV causes the most weathering damage (FigureThis means the QUV/basic cannot be used for high irradiance testing. We recommend the QUV/basic for comparative exposures where the. Open the catalog to page 11. All Q-LAB catalogs and technical brochures. Q-FOG. 9 Pages. Q-PANEL. 4 Pages. Q-RACK. 4 Pages. Q-SUN ICH Guidelines. 2 Pages. Q-SUN Xe-1, Xe-2 & Xe-3. 16 Pages.

Image 2: Range of Delta E differences from an unexposed control with corresponding ASTM Lightfastness categories. Seeing the amount of change allowed for each of the ASTM Lightfastness Categories might come as a surprise for many people who have come to expect that Lightfastness I means a color will not fade or change to any degree, or at most .Today Micom Laboratories has a 15 000 square feet test facility, in Montreal, Canada. We offer a wide range of test services all re-lated to material and product testing. MICOM LABORATORIES INC. ii If you have any questions about UV Testing and would like to speak to one of our material testing specialists, we invite you

typically found in accelerated test procedures, and subjecting the coating to a much greater thermal shock than condensation methods. This paper examines the performance of various exterior wood coatings under this modified QUV test method. Introduction Coatings for exterior millwork such as exterior siding, decks, and doors require

A Plus Coating’s QUV Tester . Test methods for QUV are available in: ASTM G154; ASTM D4329; ASTM D4587; ISO 4892-3; ISO 16474-3; SAE J2020; Other standards that QUV is part of a cyclic corrosion, such as ASTM D5894, ISO 12944-9 . Test Samples: 3″×6″or 3″×12″ all-side coated steel panels

Testing and Why is it Impo.jpg)

Assista aos vídeos da rádio que valoriza a música popular brasileira, com programas como Samba Gol, Sexta Marcha e Pagode da Trans. Veja também as lives, os shorts e as playlists da Transcontinental FM 104,7.

quv test for paint|How many hours in a Q